Block caving is an underground hard rock mining method that involves undermining an ore body, allowing it to progressively collapse under its own weight. It is the underground version of open pit mining.

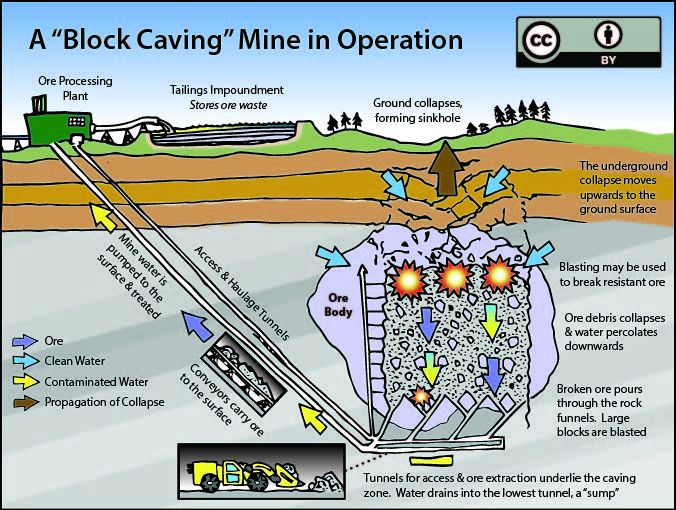

In block caving, a large section of rock is undercut, creating an artificial cavern that fills with its own rubble as it collapses. This broken ore falls into a pre-constructed series of funnels and access tunnels underneath the broken ore mass. These mineworks are sheltered from the collapsing ore inside bunker-like mass of rock, and miners extract it continuously from here. The collapse progresses upward through the ore body, eventually causing large areas of the surface to subside into sinkholes.

Block caving is used throughout the world. As future mines access deeper and lower-grade ores, this method is likely to be used more widely. Block caving is attractive because it permits very large volumes of ore to be extracted relatively cheaply, increasing production and making lower grade ores economical to mine. Although still more costly than surface mining due to the inherent difficulty of underground operations, block caving is the only underground mining technique that achieves production rates equivalent to surface mining. However, it is only suitable for ore bodies with large horizontal and vertical extents.

Block Caving Process

Block caving initially involves an elaborate pre-construction process. First, access shafts, must be drilled to a level below the ore. Then horizontal tunnels, known as haulage tunnels, are dug benearth the ore body. From this network of haulage tunnels, a series of upward-sloping tunnels (“raises”) are dug. Depending on the integrity of the rock, additional tunnels are dug higher in the rock at the “undercut” level to provide access for blasting to initiate the caving process. Blasting is used to form the “undercut”, the extensive horizontal surface from which the ore collapses. Directly below the undercut, large rock funnels (“drawbells”) are excavated by blasting upward from the raises. The mouths of these funnels abut one another, forming a continuous plane of funnel mouths where they contact the undercut. Once all the raises, funnels, and undercut are constructed, the main ore body is ready for blasting to shatter it into small pieces.

Ore debris collapses from the undercut and pours through the funnels and into the raises, where special front-end loaders collect it. In theory, no additional blasting or construction is henceforth required. As the funnels empty, the broken ore continues to drop away from the “roof” above the undercut. Unsupported, the ore roof collapses, feeding more material into the funnels. This process progresses until the ore body is exhausted. In practice, the ore body itself usually requires continued blasting to reduce it to manageable size pieces.

Trivia

_

The term “grizzly”, for the structures that catch oversize boulders, originates from when the “grizzly” was a large man with a sledgehammer, who would manually break up oversized ore blocks.

_

Even with extensive blasting of the ore body, large blocks often fall from the ore roof, and block the funnels or raises. Additional chambers, called “grizzlies”, are incorporated into raises to trap these blocks and allow them to be broken up.

If you are interested in this process, it is worth viewing in animation.

Hazards and Side Effects

Block caving creates large subsidence features on the surface, such as sinkholes. As a result of removing large continuous masses of rock, the overlying ground surface inevitably collapses to fill the void. Water contamination is a more serious concern. Both surface subsidence features and underground structural changes heavily alter water drainage patterns and groundwater flow. Water is captured by the subsidence features, and percolates downward into the fractured waste rock and remnant ore. There, it can absorb heavy metals and metalloids or react with disrupted sulfide rocks to form acid (“acid mine drainage”). Contaminated water from the mine may enter the groundwater system, pollute aquifers, and resurface to cause problems elsewhere.

From the miner’s perspective, however, the primary working hazard of block caving is that the undermined ore body may not collapse continuously. If the underground roof stabilizes, and ore is continuously removed from below, a large void may form. The roof may then collapse catastrophically, producing a destructive surge of air known as a windblast. Windblastsalone can be lethally hazardous, as was seen when a block caving collapse produced a windblast that killed 4 Australian miners in 1999. Large boulders can also cause hang-ups in the drawbells and raises, and can be dangerous to break up, requiring hydraulic breaking or blasting.

Block Caving and Pebble Mine

Block caving has been proposed for a section of the proposed Pebble Mine in southern Alaska to excavate a portion of one of the world’s largest gold, copper, and molybdenum deposits. Part of the Pebble deposit is buried roughly 1,000 to 7,000 feet underground. This section is too deep for open pit mining, and the developers have proposed to mine it by block caving.

The Pebble prospect sits at the headwaters of active salmon streams, and the potential for water contamination by block caving has been raised as a major concern. Although the Pebble area is not inhabited, a large subsidence feature at Pebble East could transform the area into a lake. Water contamination could have severe environmental effects if it reached the surface, either as contaminated springs within the lake or at downstream locations, due to acid mine drainage.

Further Reading

Created: Jan. 19, 2018